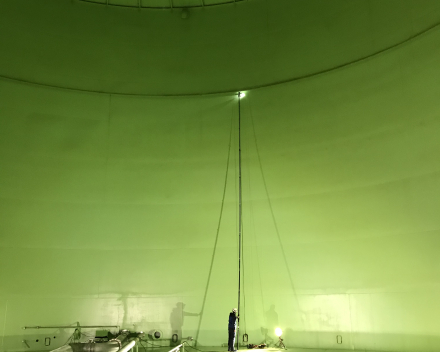

UTM thickness measurements with an A-SCAN up to a height of 24m

-

Safe and Reliable

-

Up to a height of 20 meter

-

UTM with an A-scan

-

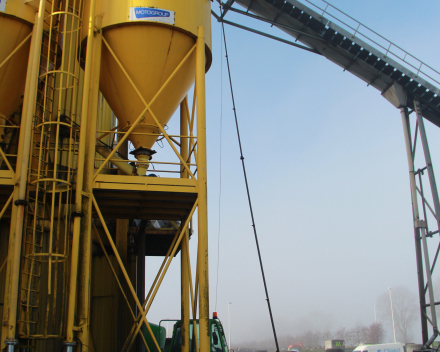

Indoor as outdoor use

-

Compared to drones, the ALTUM is not bound to any regulation

-

The UT probes used are the most accurate in the industry, with a tolerance of 0.03mm

-

1 man operation possible

-

Can measure vertical walls, sloped walls and ceilings

-

Works on all materials: steel, stainless steel, aluminium, etc...

-

Grinding module is provided if cleaning/brushing is required